EMI/EMC Testing Overview

DTB EXTENDED INFORMATION:

An article by Reyes Cortes, DTB Manager of Electrical Testing in Microwave Product Digest

EMI/EMC testing can reliably predict product performance in any electromagnetic environment. Testing can also determine the possibility of interference with other equipment, possibly degrading performance. Testing may be required in order to comply with regulations or for informational and product improvement purposes.

Electromagnetic interference (EMI) testing ensures that your product will perform properly when subject to the electromagnetic environment in which it is expected to operate. Electromagnetic compatibility (EMC) testing requires appropriate electrical and structural design, equipment installation, wiring installation, and equipment qualification to meet its intended environment.

Dayton T. Brown, Inc.’s experienced staff of electrical engineers and technicians can help bring your project to completion in a timely, low-cost manner.

EMI/EMC Tests

Services

Military & aerospace testing to all revision levels of MIL-STD-461

Testing

Testing covers the standard procedures and environmental test criteria

Testing

DTB is certified under the NSA TEMPEST Test Services Program to provide testing

Control (PTC)

Test plan development, RF performance & communications testing

Pulse (EMP)

EMP can have devastating effects on unprotected electronic equipment

Effectiveness

DTB has constructed one of the first large stirred mode chambers

Facilities

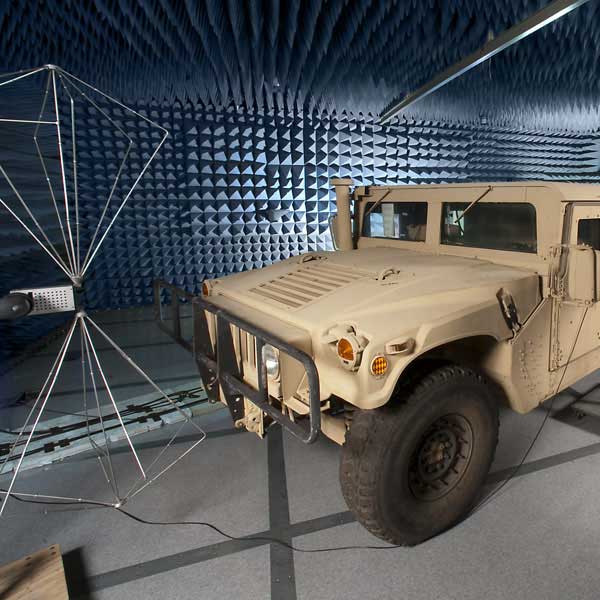

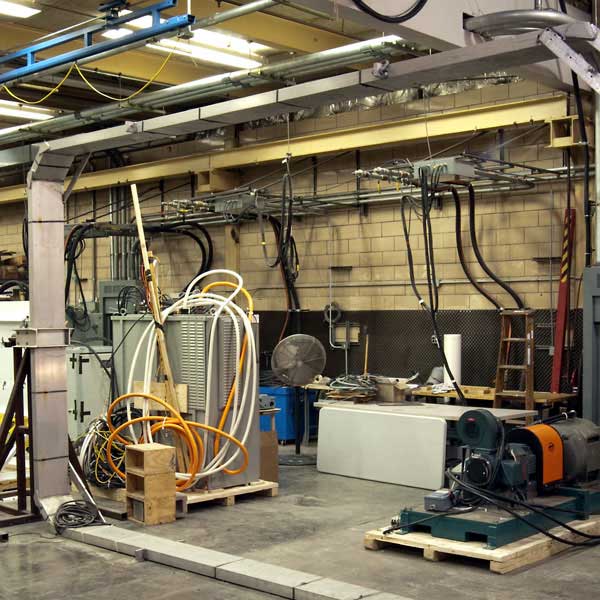

Semi-anechoic, GTEM, reverberation, and shielded screen chambers

Equipment

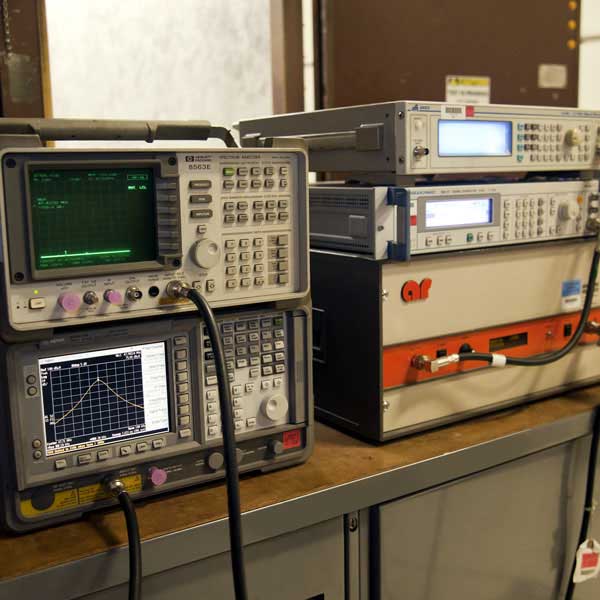

The capabilities for your test program, all under one roof

Surveys

The personnel, equipment, and power sources necessary to perform on-site testing

Testing

Test electrical systems or components for damage tolerance from strikes

Testing

Test voltage spikes, DC magnetic field susceptibility, MIL-STD-461D, E & F

Tests

Test high power, power quality, electrostatic discharge (ESD), and more